As manufacturing processes become more complex, identifying why disruptions occur has become increasingly difficult and increasingly expensive. This isn’t just because fabs are more data-rich; it’s because process complexity, product mix, and data volume have grown far faster than traditional analysis methods can manage. Leading‑edge tools now generate hundreds of sensor signals per unit and terabytes of process, inspection, and metrology data every day across thousands of sequential process steps, yet few manufacturers can combine and analyze all this information in real time.

At the same time, fabs are processing higher product mix on the same lines i.e multiple nodes, product variants, and customer configurations, requiring complex coordination between planning, engineering, and operations that traditional RCA wasn’t designed to support.

According to a Siemens survey, downtime in a large manufacturing plant can cost up to $129 million per year. Yet many organizations still rely on reactive troubleshooting methods that focus on symptoms rather than true root causes.

With the rise of Industry 4.0, manufacturers now have access to a new generation of AI-driven technologies that fundamentally change how production issues are identified and resolved. One of the most impactful of these technologies is AI-powered Root Cause Analysis (RCA).

In this article, we’ll explore:

- Why RCA is critical in modern semiconductor manufacturing

- The limitations of traditional RCA approaches

- What AI-driven RCA is and how it works

- The tangible benefits of adopting AI-powered RCA

By the end, you’ll have a clear understanding of how AI-driven RCA helps manufacturers reduce downtime, improve yield, and strengthen overall operational performance.

Why Root Cause Analysis Matters in Manufacturing

Root Cause Analysis (RCA) is a structured methodology used to identify the true origin of a problem and implement corrective actions that prevent it from happening again.

When applied effectively, RCA enables manufacturers to:

- Improve product quality

- Reduce unplanned downtime

- Minimize scrap and rework

- Increase Overall Equipment Effectiveness (OEE)

The real power of RCA lies in its ability to move beyond surface-level fixes.

For example, teams may repeatedly tweak process settings to recover yield. But if the real issue is upstream material variability or a hidden interaction between process steps, performance will continue to fluctuate. Without addressing the root cause, manufacturers remain trapped in a cycle of firefighting rather than true process control. To unlock the full value of RCA, manufacturers must use methods capable of uncovering these hidden, systemic issues.

Traditional RCA Methods and Where They Fall Short

For decades, manufacturers have relied on traditional RCA techniques rooted in human expertise and manual analysis. Two of the most commonly used methods are:

Fishbone (Ishikawa) Diagram

A visual cause-and-effect chart that helps teams brainstorm potential causes across categories such as people, machines, materials, and methods. While useful for structured thinking, it often generates too many possible causes, making it difficult to identify the true driver of the problem.

The 5 Whys

This method involves repeatedly asking “why” (typically five times) to drill down to the underlying cause of an issue. While simple and intuitive, its effectiveness depends heavily on the experience and assumptions of the individuals involved.

Key Limitations of Traditional RCA

Despite their widespread use, traditional RCA methods face significant challenges:

- Time-consuming analysis: Manual data collection and investigation can take days or weeks, prolonging downtime.

- Limited ability to handle complexity: Modern manufacturing systems involve thousands of interacting variables that are difficult to analyze manually.

- Lack of real-time insights: Traditional RCA typically relies on historical data, delaying corrective action.

- Subjectivity and bias: Outcomes often depend on individual expertise and interpretation, leading to inconsistent results.

In fast-moving, data-rich manufacturing environments, these limitations can significantly impact productivity and profitability.

How AI-Driven Root Cause Analysis Solves the Limitations of Traditional RCA

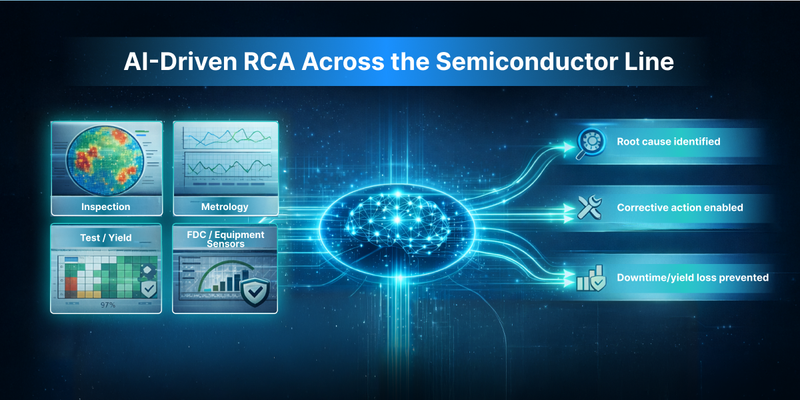

In semiconductor manufacturing, meaningful control and review already happen at four stations: FDC, inspection, metrology, and electrical test. AI-driven RCA works by embedding analysis directly at these points, instead of running isolated, after-the-fact investigations.

At the FDC layer, traditional RCA looks at alarms after a failure is visible. Engineers scan logs, silence nuisance alerts, and search for obvious SPC violations. AI changes this by learning normal tool behavior across hundreds of parameters and recipes. It detects combinations of small drifts that consistently precede downstream issues, even when each signal is individually within limits.

For example, AI can link a subtle RF instability and pressure drift in a specific chamber step to yield loss seen days later. Without AI, this would appear as random variation and could take weeks to investigate, if it is found at all.

At inspection, traditional RCA focuses on defect counts or density and predefined classes. Subtle changes in defects or spatial distribution are often missed or reviewed only after yield impact. AI analyzes inspection images at scale and groups defects and wafers based on visual similarity and spatial patterns, then correlates them with tool history and process steps. This makes it possible to identify new defect signatures early and trace them back to a specific tool, chamber, or process condition. Issues that previously required multiple review cycles and subjective analysis can be narrowed down automatically.

At metrology, engineers typically rely on univariate SPC charts and sampled data. Small shifts that stay within control limits are ignored, even if they affect downstream performance. AI models multivariate relationships across CD, thickness, overlay, stress, and process conditions, and links these trends to inspection and test outcomes. This allows detection of slow, systematic drift that explains later failures. Many of these issues are never escalated using traditional methods because nothing is technically “out of spec.”

In electrical test, RCA is usually reactive. Failures are analyzed after value has already been added, and correlation back to upstream steps is manual and time-consuming. AI connects test failure patterns directly to upstream defect signatures, metrology trends, and FDC events, identifying the most likely causal path instead of a long list of suspects. Problems that previously required weeks of cross-team data pulls can be narrowed down in hours.

Across all four stations, AI has the potential to accelerate manual RCA with continuous learning across large, noisy datasets. It reduces subjectivity, handles complex interactions, and surfaces root causes that are either too subtle or too distributed for traditional RCA to find. The result is faster resolution, fewer repeat issues, and earlier intervention often before yield or downtime is visibly impacted.

In an Industry 4.0 environment, RCA cannot be a periodic exercise. It must be a continuously running system; one that learns, connects, and adapts as fast as the factory itself.