Introduction

Over the last few years working closely with fabs and OSATs, we’ve seen semiconductor manufacturing reach a new level of sophistication.

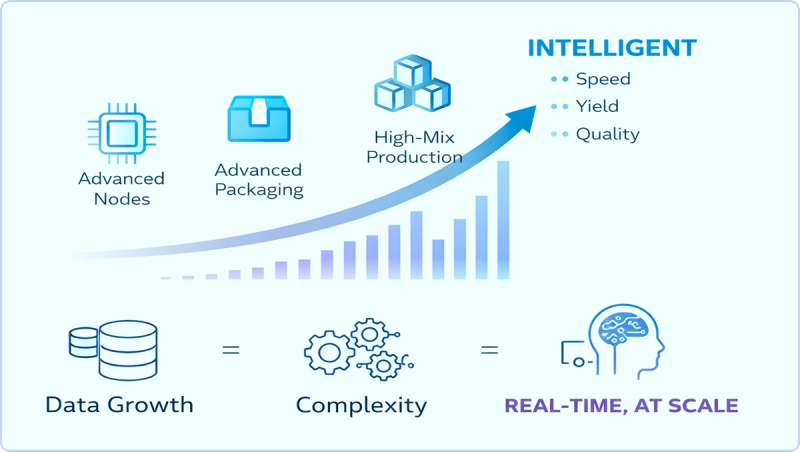

Advanced nodes, packaging, and high-mix production are scaling rapidly. Data from tools, metrology, inspection, and test keeps growing in volume and richness. At the same time, speed, yield, and quality expectations are higher than ever.

As complexity compounds, the industry is entering a new phase of intelligence operating in real time, at scale.

Vision for the Industry

We believe future fabs will be intelligent by default, where decisions are guided by real-time insight rather than retrospective analysis.

It’s no longer impossible to imagine a lights-out factory where AI agents manage massive volumes of process, metrology, inspection, and test data, turning it into actionable intelligence.

These agents will detect hidden patterns, spot subtle drifts, and surface early signals that matter, working 24/7 to:

- Detect process deviations in near real-time

- Trace issues to their source and

- Act in real time, before yield and quality are impacted

AI is no longer optional, it's essential to help semiconductor manufacturers produce more with less and adapt faster in a decade defined by:

- Rapid technology shifts

- Shorter product lifecycles

- Rising manufacturing complexity

- Scarcity of expert engineers

Our Journey

Sixsense.ai started with a simple but hard question:

“Why does it still take weeks or months to understand yield and quality issues in a data-rich fab?”

Since then, we’ve focused on building AI systems designed for real production environments. That journey has included deploying AI across fabs in Singapore, Taiwan, Malaysia, Israel, and the US working closely with manufacturing, yield, and quality teams to deliver measurable impact.

Today, SixSense.ai is trusted by leading manufacturers across technology nodes, advanced packaging, and A&T, including GlobalFoundries, JCET, Raytek, and others. We have also partnered with well known machine vision companies to ensure AI integrates seamlessly into existing inspection and manufacturing flows.

Measurable Impact

Early results consistently show:

- Dramatic reduction in operator dependency

- Autonomous containment of yield-impacting issues

- Lower false alarms and overkills

These wins demonstrate that AI is not just a concept, but a production-ready system capable of delivering real value in complex fabs.

The Next Era

The semiconductor industry is entering an era where data volume keeps growing but time, talent, and margin do not. The real question is:

“Can fabs continue to rely on manual analysis and static rules or is it time for AI to become the decision engine of manufacturing?”

We believe the next leap in the decade ahead will come from data — how we collect it, connect it, and act on it , turning today’s complexity into seamless, intelligent action.