At SixSense, our focus has been to bring AI into semiconductor manufacturing in a way that works in production. Our initial focus has been AI-based Automated Defect Classification (AI-ADC), software that integrates with OEM inspection tools and DMS systems to automatically classify defect images at scale. Today, AI-ADC is deployed in production at multiple foundries and OSATs and processes millions of live inspection images every year.

In 2025, our focus was on scaling AI-ADC across Asia and the US. We expanded our footprint in Taiwan with Raytek, one of Taiwan’s leading advanced packaging companies. We also received recognition from our long-term customer GlobalFoundries for AI innovation and launched new product capabilities to further strengthen our ADC platform.

In 2026, we will continue scaling ADC with more customers and work with inspection equipment partners to enable real-time, in-machine defect classification, moving beyond offline post-inspection analysis. At the same time, we are expanding our scope beyond ADC by applying AI to deviation control across fabs. This includes new AI applications for Test, Metrology, and FDC control points, enabling broader automation, earlier detection, and more proactive yield management.

Below are key highlights from 2025 and how they shape our focus for 2026.

1. Production deployment with Raytek in Taiwan

In 2025, SixSense worked with Raytek to support their smart manufacturing initiatives using AI-powered inspection. The deployment focuses on reducing manual defect review, enabling faster and more consistent defect classification, shortening root-cause investigations, and supporting faster wafer and packaging disposition decisions.

With Raytek as a customer, SixSense deepened its engagement in Taiwan, the global epicenter of semiconductor manufacturing, supporting the move toward more automated and intelligent production workflows.

2. Product releases enabling faster model deployment

In 2025, we released new features in AI-ADC to reduce the time and effort required for defect experts to deploy models in production.

Clustering for data review

The system groups similar defect images together and highlights unusual or mislabelled ones. Instead of manually reviewing thousands of images, engineers can now review clusters, outliers, and patterns. This reduced manual review time by over 50% and improved training data quality.

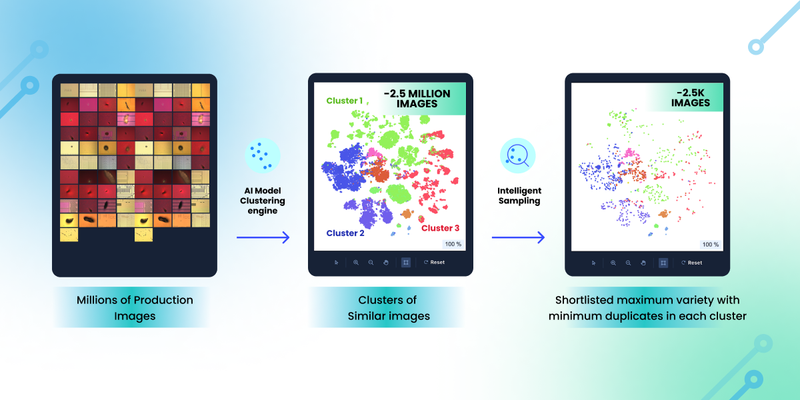

Smart data selection

The system automatically selects a small but diverse set of images from each defect class, capturing variation while removing redundancy. The number of images per class is auto-determined by AI to ensure minimal yet high-quality high coverage training data. This enabled customers to launch production-ready models in 2–3 days, while reducing data volume by up to 70%. Selecting data correctly upfront also reduced the need for repeated retraining once models were live.

AI-Vision Foundation model

We integrated newer AI approaches such as Vision Transformers, self-supervised learning, and diffusion models into the platform. This resulted in a single model capable of supporting multiple devices, handling 20–30+ defect classes, and maintaining over 95% accuracy with 0% escapees in production.

3. GlobalFoundries AI Innovation Award

In 2025, GlobalFoundries recognized SixSense with the AI Innovation Award, validating the impact of AI in live production environments.

SixSense AI-ADC has been deployed in GlobalFoundries’ 200mm and 300mm fabs since 2022. The system reduced manual inspection workload by over 90% while operating across different inspection OEMs and tool generations. This enabled AI deployment at scale without dependence on specific hardware platforms.

Looking ahead to 2026

We will continue scaling ADC with more customers and inspection tool partners, moving toward real-time, in-machine defect classification. This allows defects to be detected and classified as wafers are scanned, reducing manual review, speeding up decisions, and improving automation.

ADC will also expand to 3D defect classification, analyzing depth, shape, and structure to identify complex defects that 2D images cannot capture, further improving reliability and reducing operator effort.

Beyond ADC, we are building AI applications for deviation control across fabs. This includes linking defect data to process tools to identify recurring issues, connecting final test results to inline inspection and metrology signals to detect early failure signs, and deploying predictive models at key control stations to flag potential lot-level problems before they impact yield.

These efforts together will make inspection, analysis, and root-cause detection faster, more automated, and more actionable.